-

Hacettepe Teknokent, 4.Arge Binası

Hacettepe Teknokent, 4.Arge Binası

B-Blok No:9, Çankaya Ankara Türkiye -

+90 312 227 02 64

+90 312 227 02 64

-

info@hoytek.com.tr

info@hoytek.com.tr

-

Hacettepe Teknokent, 4.Arge Binası

Hacettepe Teknokent, 4.Arge Binası

B-Blok No:9, Çankaya Ankara Türkiye -

+90 312 227 02 64

+90 312 227 02 64

-

info@hoytek.com.tr

info@hoytek.com.tr

ROBOTIC SOLUTIONS IN OFFSHORE INDUSTRY

With the rapid progress of the developing industrialization, the energy demand continues to increase. Research on new sources of fossil fuels to meet this need is also growing rapidly. Today, fossil fuels are still being used as the greatest resource to meet the need for new energy sources (solar energy, wind energy, etc.) and they are getting ineffective to meet the needs. 80% of our energy needs are still met by fossil fuels; we meet 50-60% of this need as oil and gas.

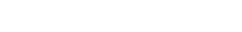

Oil production, which was 1 million barrels per day in 1940, rose to 24 million per day in 2009. After 2009, oil production has reached 80 million barrels per day in 2015 with increasing needs and developing techniques. One-third of this production is made from offshore oil, and the percentage of off-shore oil increases with the reduction of oil reserves by day and the ease of exploration of underwater resources.

With the start of the extraction of fossil fuels from underwater sources, technical requirements and problems became more observable. One of the examples was the Deepwater Horizon catastrophe that took place in the Gulf of Mexico on April 20. As a result of the explosion on the oilrig that BP rented from 2001 to 2013, 11 people working on the platform died and 17 people were seriously injured. After the explosion, 757 million liters of oil were scattered over the sea and local fishermen, mainly underwater life, state resources and BP, did suffer major damage. For the cleaning operation that started in 2010, 48,000 people, 6500 vehicles and 4000 kilometers of field work were done. In April 2014, the US Coast Guard (US Coast Guard) ended its efforts and stated that 14 Billion US Dollars and 70 Million Man / Hour have been spent so far.

The cause of the catastrophic event has been found to be the pipeline and well supervision not done in time. New regulations have been introduced by the European Commission after this event and a new initiative has been started to make the oil exploration operations safer. Many cases have been filed against the BP company after the incident and the company has been obliged to continue working until the end of the cleaning.

After the Deepwater Horizon, new regulations and techniques have been introduced to protect human and marine life and to make off-shore operations more controlled and effective. One of these techniques is the use of ROVs (Remote Controlled Unmanned Submarine) and AUVs (Autonomous Underwater Vehicle).

The use of robots in offshore fossil fuel applications has made operations safer, cheaper and more efficient. AUVs used for research missions and ROVs that can operate 24/7, reduced the daily costs of divers used in the sector and also increased effective production. There are 3 stages that apply during the oil extraction in the sea:

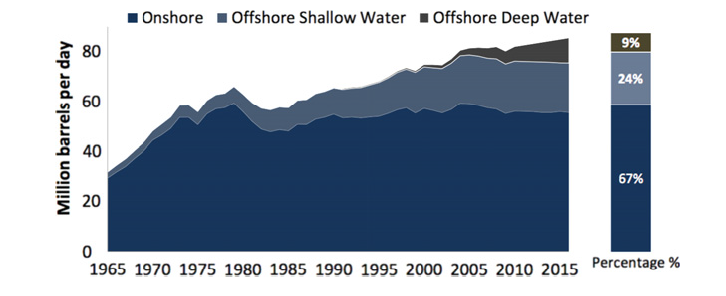

Discovery and Oil Extraction (Upstream): At this stage, the sea bed is scanned with ROV and AUVs and necessary information is gathered. After that the location of the oil / gas resources is determined by referring to the data by Geochemists and Geophysicists, and then the drilling operation is performed at the determined location. The appropriate oilrig is placed in the mouth of the opened well considering the sea depth and reserve size. Petroleum platforms are selected as fixed or mobile, taking into account the depth of the well, the size of the reservoir, the duration of the operation and the cost. ROVs are actively used in the installation and maintenance of fixed platforms. On mobile platforms, both ROV and AUVs are constantly used for maintenance / repair and monitoring of environmental conditions.

Before the platform is set up, ground survey and environmental condition operations are carried out by AUVs. Then, ROVs are used to determine the location of the fixing points of platform legs. In addition, ROVs used in drilling support have reduced the duration and cost of drilling. At the same time, if the work to be done is in the depths or conditions that divers can not work, these operations are also carried with ROVs. In the depths where divers work, both dive surveillance and diver assistance are provided by ROVs.

After the establishment of the oilrigs, oil extraction processes start. At this stage, the inspection and maintenance / repair works are carried out by ROVs. In addition, environmental effects are observed with AUVs and the necessary data are collected for safe operation. In addition, since the use of underwater valves and equipment that has 7/24 working capacity, remote control systems are used to provide an affordable solution.

Processing, Transportation and Storage (Midstream): At this stage, the first processing operations of oil or gas are carried out from platforms that are now activated and transferred to transport (or storage). In this section ROVs are used for the maintenance and supervision of pipelines and monitoring the underwater parts of transport vessels, if necessary.

Refining and Distribution (Downstream): At this stage, the oil or gas transferred to the facilities located on the coast is generally refined and distributed. For underwater equipments or facilities, ROVs are used for their activation and monitoring.

ROVs and AUVs, which generally play an increasing role in the discovery and extraction of fossil fuels; are the perfect solution to replace the divers in deep sea wells (400m to 1500m deep) and ultra deep sea wells (1500m deep). ROVs are also used in shallow marine wells (less than 400m depth) for their payload capacities as well as for long-term observation and maintenance / repair tasks. Thanks to advancing technology and ever-increasing robot mobility, ROVs can perform almost any task divers can do. The Deepwater Horizon catastrophic problems were solved by using Schilling Robotics TITAN, ATLAS, CONAN and ORION robot arms at 1511 meters depth and the operators were able to easily solve the problems remotely at depths that divers can not reach. These arms, which can be easily mounted on ROV systems, and wide sensor options have made it possible to achieve deep and ultra-deep water operations.

We can classify tasks with ROVs as follows:

- Error Checking

- Magnetic Particle Inspection (MPI)

- Flexion Control as a Result of Current Fluctuations

- Vortex Flow Measurements

- Measuring Fluctuation of Flow Fields (ACFM)

- Finding Submerged Components

- Current Exchange Potential Drops

- CR

- Ultrasonic Tests

- General Visual Controls

- Close Visual and Photographic Controls

- Corrosion Control

- Cathodic Protection Potential Measurements

- Wall Thickness Measurements

- Other Audit Tasks

- Audit-related cleanups

- Control-related grinding operations

- Audit-related setups

- Welding

- Photographing

- Taking Video Recordings

- Cathodic Protection Readings

- Tasks Related to Construction

- Trenching the Pipeline

- Lifting

- Pulling

- Bolt / Mechanism Operations

- Sand Bag Support Layout and Assistance Operations

- Making and Separating Operations

- Equipment / Payload Transport

- Underwater Structure Cleaning

- Underwater Structure Measurements

In addition, ROV and AUV operations are categorized as follows:

Commercial Operations: Under this category, there are commercial operations (mostly in the oil and gas sector). AUV and ROV systems are used for underwater observation, inspection, repair, maintenance, welding, cutting, recovery and sampling operations.

Oceanographic Research Operations: Under this category, AUV and ROV systems are used by scientific research institutes to reach the points of interest under water to recover data (underwater life index information, environmental conditions, pollution, new life forms and mineral information).

Military Operations: ROVs and AUVs are actively used by navys for cost-effectiveness in discovery / surveillance and rescue missions. They are also used for anti-submarine and anti-mine missions.

Engineering Researches: In the light of ever-evolving technologies, AUVs and ROVs used for R&D studies for both offshore and subsea new technologies.

As of 2010, ROV sales in the global market amounted to 850 Million Dollars and AUV Sales amounted to 200 Million Dollars. In ROV sales, 50 percent of this amount is in the oil and gas industry, 25 percent in the defense industry, and the remaining 25 percent in the research field. Since the AUV market is smaller, more than 50% of the sales are in defense industry and the rest are in the oil, gas and research industry. 70 percent of the sold AUVs operate at depths less than 200m. It is expected that the AUV market, which has been growing since 1985, will reach 2.3 million USD by the end of 2019. 75% of the currently used AUVs were produced between 2001 and 2005, and this number is seen as a realistic result, due to renewal work in result of developing technology. Since AUV is a newer technology, 66-75% of their costs are the main systems (this cost is around 40% in ROVs) and the remaining costs are generated by sensors and devices.